Insulation Piercing Connector

Description: The covered conductors -to- covered conductors connection connector is designed for joining aluminum conductors to aluminum conductors in non-tension applications within medium-voltage networks up to 36 kV, without the need to remove the conductor’s insulation. The connector is watertight with silicone grease-coated teeth. The nominal thickness of the conductor's insulation should be between 2.3 and 3.3 mm. This connector can be used with Cover Conductor and can be applied with a B3-sized cover for added protection

IPC0101

IPC0102

Insulation Piercing Connector

Description: The bare-to-cable connector is designed for electrically connecting aluminum bare conductors with insulated conductors in non-tension applications within medium-voltage networks up to 36 kV. One side of the connector is toothed for attachment to the covered conductors, while the other side has parallel grooves where the bare conductor is placed. The connector is watertight with silicone grease-coated teeth. To prevent water ingress, short circuits, and to enhance network reliability and stability, the B3 insulated connector cover should be used.

TE0101-TE0102

Tension Clamp for Dead-end Covered Conductors

Description: This type of clamp is specifically designed for tension insulated conductors and is used for medium-voltage overhead covered conductor system. The connection method is typically wedge-shaped, without the need for fastening the bolts or removing the conductor’s insulation.

SU0101

Suspension Clamp

Description: This suspension clamp is designed for securing covered conductors in overhead lines as they pass through angles or are supported by suspension insulators. Equipped with rollers to ease network installation, the clamp features two aluminum clamping pieces to ensure secure attachment and maintain electrical potential with the covered conductor. These clamping pieces can also establish electrical connections with arcing horns in suspension insulators. For enhanced reliability, network stability, and protection against water ingress and short circuits, a cover is recommended.

PAD0101

Power Arc Device

Description: This product serves as a network protection device against lightning, used on tension and suspension insulators in combination with tension clamps (codes TE0101, TE0102) and suspension clamps (code SU0101). It is specifically designed for networks with phase spacing greater than 60 cm. The air gap for arc protection can be adjusted between 95 to 230 mm for voltage levels ranging from 12 to 36 kV.

PAD0102

Power Arc Device

Description: This product is specifically designed to protect covered conductors from lightning. It should be used on networks with silicone insulators where the phase spacing exceeds 60 cm. The gap between the prongs is adjusted with an M16 full-thread bolt. The air gap for arc protection can be set between 95 to 230 mm for voltage levels ranging from 12 to 36 kV.

APD0101

Arc Protection Device

Description: This product is designed to protect covered conductors from lightning, specifically for networks where the phase spacing is less than 60 cm. It also includes a 25 mm² aluminum wire, 2.1 meters in length, which is wrapped around the insulator and conductor, then secured in the clamp and next to the prong.

HT0101

Helical Tie HT0101/1 to HT0101/6

Description: This product is specifically designed to secure covered conductors to the top groove or neck of the insulator, ensuring firm attachment. In other words, it is used to fix the covered conductor to the insulator. It features an insulating cover that prevents damage to the conductor's coating and helps avoid partial discharges. The installation is very easy and requires no tools. Color-coded markings are used to simplify size selection.

L.L.CO0101

Live Line Connector

Description: This product is designed for branching into covered conductors in live-line conditions. One of the advantages of this type of connection is that it can be opened and closed from below using a hot stick. There is no need to remove the conductor's insulation for installing this connector, which helps preserve the integrity of the conductor's insulation and ensures network stability. The teeth of the connector are coated with a special silicone grease to watertight the connection.

Live Line Connector L.L.CO0102

Description: This product is specifically designed for branching conductors in live-line conditions. One of the advantages of this connection model is the ability to open and close it from below using a hot stick. There is no need to remove the insulation from the conductor for installation, and the design of this clamp allows for operation with a hot stick. It is important to note that all components of this fitting are made from aluminum and stainless steel, ensuring that the bolts can be easily tightened and loosened.

L.L.CO0102

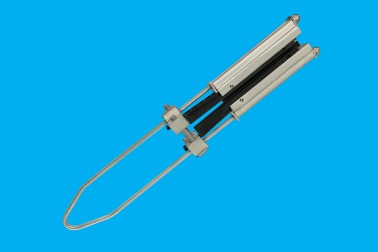

Hotline Connector Stirrup

Description: This bracket is specifically designed for tapping from insulated live overhead lines and earthing, using L.L.CO0101 and L.L.CO0102 hotline saddle connectors. It is made of corrosion-resistant aluminum alloy with high electrical conductivity.

STIRRUP